Originally Posted by

93 525 Paul

Working the shortblock now. Don't like much of the CraigsList shortblock, may only end up using the block and caps and use everything else from mine. The front cover is corroded, the plunger in the oil pump is scored etc...

More updates to come.

Well, I said that exactly to the day a YEAR ago. I have in that time decided to only use the bare shortblock (block, main caps, crank, rods and pistons) because all my stuff was in better shape. Had the block hot tanked and honed and bought all the rebuild items. Started to do the short block assembly this time last year and baseball season for my son started (coaching) and poof there went every spare moment through summer all stars. Spent fall working on my Lincoln (Klincoln? with leaking sunroof, dying COPs, failing timing chain tensioners etc.) So I'm back in the saddle.

Block all cleaned, painted, ready.

I've installed the crank with new bearing inserts, standard, it (no surprise) mics out as new. I've assembled and installed all the carefully cleaned piston assemblies with spotless ring grooves, nice new ring packs, new bearings.

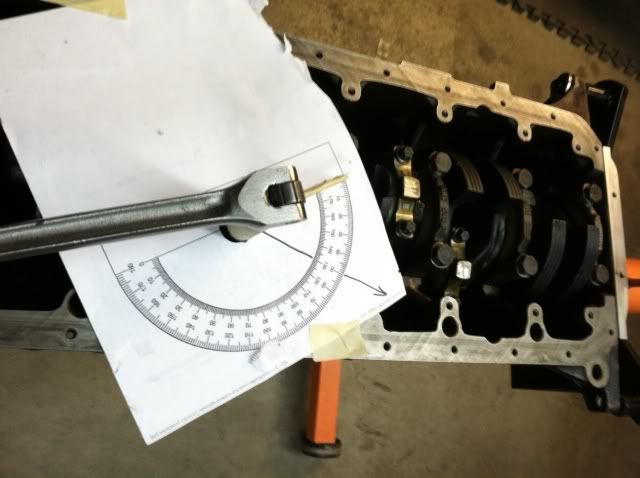

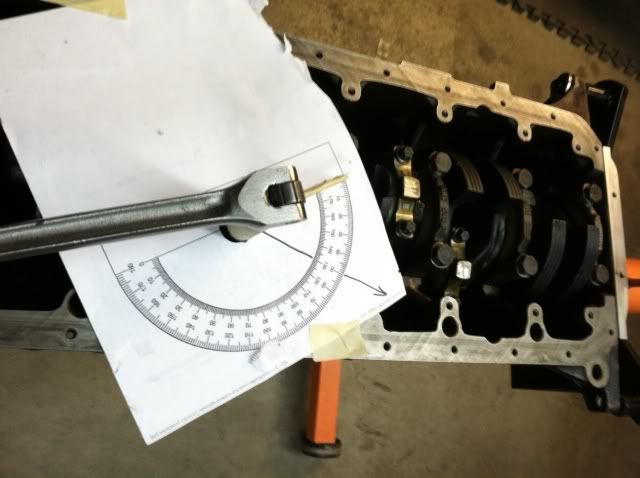

Here I'm using my printed protractor to tighten the mains and rods to the proper torque angle. 20nm then 50* for the mains and 20nm then 70* for the rods.

Seems backwards, seems like that's a HUGE amount of torque for the rod capscrews to hold. Well, mother Beemer knows best.

Hoping to finish the entire engine assembly this weekend. Kid's not playing baseball this season, golf team and no coaching for me.

Link to my M50 engine rebuild thread

http://www.bimmernut.com/forum/showthread.php/43339-M50-Eng-4L30E-Trans-RRR-Far-More-Than-I-Ever-Expected?highlight=93+525+paul

Reply With Quote

Reply With Quote